Produktion

100 Jahre PRODUKT- UND

PROZESSOPTIMIERUNG

Zeit-Intensiv

Zur Lederherstellung sind umfangreiche Arbeitsprozesse nötig.

Um qualitativ hochwertiges Leder zu produzieren, bedarf es bis zu 35 anspruchsvolle Verarbeitungsschritte. Seit Beginn unserer Lederherstellung im Jahre 1923 haben sich viele Abläufe und Anwendungsverfahren geändert. Was früher einzelne Gewerke ausgeführt haben, bündeln wir heute an einem Standort und nutzen modernste Technik. Doch selbst aktuelle Fertigungsanlagen machen aus einer Haut nicht automatisch ein hochwertiges Leder. Neben Hightech-Maschinen benötigt die Herstellung ebenso das Know-how sowie die Erfahrung sachkundiger Fachleute. An diesem hohen handwerklichen Anspruch halten wir auch nach mittlerweile 100 Jahren eisern fest.

Gerben

Geeignete Rohhäute beziehen wir über Rohwarenhändler oder direkt von Schlachtern aus Deutschland und Österreich – Ländern mit hohen Tierschutzstandards. Zum Reinigen gelangt die Rohware direkt in unsere Hasplen – riesige Holzgefäße, die wie Wäschetrommeln anmuten. Nach dem 48-stündigen Reinigungsprozess entfernen wir mit Messerwalzen von der jetzt „Blöße“ genannten Haut letzte Unterhaut-Bindegewebe-Reste. Als nächstes erfolgt das Spalten mit der Spaltmaschine mit Hilfe eines Bandmessers, um eine gleichmäßige Stärke der oberen Spalthaut (Narbenspalt) zu erzielen.

In der Wasserwerkstatt wird die obere Spalthaut (Narbenspalt) gegerbt. Drei Gerbfässer setzen wir in der Wasserwerkstatt ein. In diesem Prozess wandelt sich die verderbliche Blöße innerhalb von 24 Stunden in ein haltbares Produkt. Aus der natürlichen Eiweißstruktur der Haut wird beim Gerbprozess ein jahrzehntelang haltbares Leder. Als Gerbstoff setzen wir generell auf hochwertige Mineralsalze, die das Leder blau verfärben, weshalb nach Abschluss dieses Vorgangs die Haut „Wetblue“ genannt wird.

Vorbereitung zum Färben

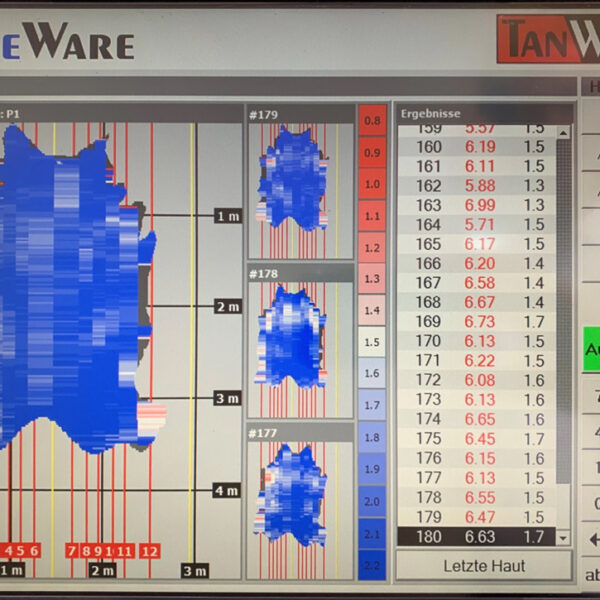

Die Wetblue-Häute durchlaufen als nächstes die Abwelkmaschine, die überschüssiges Wasser aus dem Leder presst. Hierbei wird eine Flächen- als auch Stärkemessungen vorgenommen. Von jeder Haut wird ein topografisches Rastermodell der Hautstärke erstellt – als Hilfe für die darauffolgende Wetblue-Sortierung. Zur sorgfältigen Kategorisierung erfolgt eine Kontrolle nach definierten Grundkriterien bezüglich der Anzahl, Häufigkeit und Ausprägung von Naturmerkmalen. Sämtliche daraus resultierenden Informationen erfasst eine Datenbank. Wir differenzieren bis zu 16 Sortimente und lagern sie auf Paletten, bis die Ware für Kundenaufträge aktiviert wird.

Kommt ein Auftrag ins Haus, wird die Ware aktiviert und an der Falzmaschine sorgfältig und behutsam auf die benötigte Stärke gebracht. Anfallende Falzspäne sammeln wir und verkaufen sie an einen Hersteller für Lederfaserstoffe weiter.

Färben

Die Färbefässer werden mit Wetblue-Ledern gefüllt und Farbstoff-Effekte sowie Nachgerbstoffe beigegeben. Bei Zuführung von warmem und enthärtetem Wasser bewegen sich die Fässer kontinuierlich mit wechselnder Richtung. Dabei lösen sich die Farbstoffe, Fette usw. auf.

Je nach Rezeptur dauert der Färbeprozess zwischen drei bis zwölf Stunden. Jetzt spricht man von Anilinleder, auch Crustleder genannt.

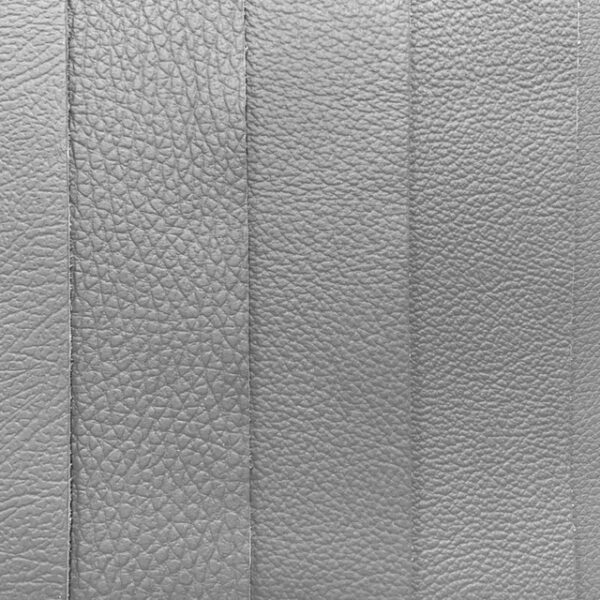

Leder wird bei uns ausschließlich mit qualitativ hochwertigen Farbstoffen „durchgefärbt“, was an den gefärbten Schnittkanten ersichtlich ist.

Das Färben hat neben der Farbgebung auch Einfluss auf Haptik, Optik und Geruch.

Vorzurichtung

Die Ausreckmaschine presst überschüssiges Wasser aus dem Leder. Am Klammerrahmentrockner wird das Leder mittels Klammern zur anstehenden Trockung fixiert. Anschließend durchlaufen die Häute innerhalb von sechs Stunden den Trockenkanal.

Die Fasern der Leder sind aufgrund der vorherigen Arbeitsschritte sehr fest geworden. Die Stollmaschine lockert diese Fasern auf und macht das Leder dadurch wieder weicher.

Falls Kunden eine individuelle Prägung wünschen, durchläuft das Leder die Prägemaschine, die mit Hilfe von Druck und Hitze verschiedene Designs auf das Leder überträgt.

Im rotierenden Millfass lockert sich das Fasergefüge weiter auf und das Leder wird noch geschmeidiger. Zusätzlich kann bei Bedarf Wasser oder Griffmittel mit eingearbeitet werden – je nachdem welcher Artikel produziert wird.

Zurichtung

Zur weiteren Oberflächenbehandlung erhält das Leder eine Schutzschicht, wofür wir einen gewünschten Farbton aus verschiedenen Pigmenten und Bindemitteln anmischen. Unsere Mitarbeiter stellen die Farbe so lange ein, bis die gewünschte Nuance erreicht wurde. Kundenwünschen sind hierbei fast keine Grenzen gesetzt. Sämtliche Farben sind wasserbasierend und unter Verwendung eines lösungsmittelfreien Zweikomponenten-Systems.

Auf die Lederoberfläche wird eine Grundierung aufgetragen, entweder gedruckt mit einer Walze oder im Spritzverfahren. Die aufgetragene Appretur (Schluss- oder Schutzlack) schützt das Leder vor Anschmutzung und erhöht die Gebrauchseigenschaften.

Qualitätssicherung

Während des gesamten Herstellungsprozesses kommt es zu wiederholten Qualitätskontrollen und der Erfassung von Analyse-Daten.

Hierbei werden Reibechtheit, Dauerfaltverhalten, Reißfestigkeit getestet.

Je nach Artikel wird auch ein Flammtest durchgeführt.

Lager

Im Lager wird elektronisch die Fläche jeder Haut ermittelt und zusammen mit der Chargennummer auf die Rückseite gedruckt. Dank der zugeordneten Nummern lässt sich jede einzelne Haut zurückverfolgen – sämtliche Arbeitsschritte sind entsprechend dokumentiert. Jede Haut wird im Lager final geprüft und in verschiedene Qualitätsstufen, den Sortimenten, eingestuft. Um Faltenbildung vorzubeugen, werden bei uns sämtliche gelagerten Leder als ganze Haut auf Böcken abgelegt.

Versand

Wir versenden Kleinmengen (ein bis neun Häute) eingeschlagen im Karton per Paketdienst.

Größere Mengen (je nach Lederstärke 25 bis 80 beziehungsweise 30 bis 110 Häute)

im Karton auf einer Palette gepackt per Spedition. Kleinmengen von 1 bis 2 Häuten gehen pro Röhre gerollt als Langpaket. Großmengen von 30 bis 100 Häuten werden gerollt in einer Langbox auf der Palette versendet.